Hot work operations such as welding, cutting, soldering, and any activity involving open flames or excessive heat can create numerous health and safety hazards. These activities also carry the risk of industrial fires, which can be disastrous for your employees, business premises, and projects under construction. Wildfires cause death, injury, and hundreds of millions of dollars in damage annually. For this reason, in this article from Ganjineh Pavan’s articles, we will examine the dangers of hot activity and methods of prevention and improvement of safety to minimize possible risks.

The importance of knowing the dangers of hot work

Hot work is a particular threat in industrial environments and the construction sector, as it is the cause of numerous fires in workplaces and buildings. For example, according to figures from Fire and Rescue Scotland, there were 180 fires in the construction industry in 2018, of which 143 (79%) were the result of hot activity. 51 fires in this period were caused by welding or cutting equipment, 22 by manufacturing equipment, and 23 by furnaces or other services. These fires left 21 injured.

Conducting hot activities safely is an important part of fire safety in the workplace, but to do so, you must identify hot activity hazards and implement control measures that effectively reduce hazards and keep workers safe has it.

In this article, we’ll explore a variety of this type work hazards and the control measures you can use to help keep your employees and workplace safe during hazardous activities.

What is hot work?

Hot work is any work that requires the use of an open flame or the application of heat or friction that may cause sparks or heat.

The British Standards Institution (BSI) in BS 9999 defines this term as:

Hot work is any method that may involve or have the potential to generate heat, sparks, or flames sufficient to cause a fire.

Examples of this type activity include welding, flame cutting, soldering, brazing, grinding, and the use of other equipment used with flame.

In general, the most common examples of hot activity and those that can create significant hazards without proper precautions include:

-

- Brazing and welding of rice

-

- Gas/electric welding cutting machine

-

- Grinding wheels and cutting discs

Various industries, especially construction, may require on-site hot work as part of normal work activities. Also, thermal work is often done as part of the contract work that is common in construction.

Hot work hazards to consider in your risk assessment

Working with high levels of heat and open flames is dangerous, but to conduct a thorough risk assessment and implement effective control measures, you must accurately identify the hazards posed by hot work activities. These activities generally include the following:

Electrical hazards of thermal work

Most hot activity involves the use of electrical equipment, so workers will be exposed to electrical hazards such as the risk of equipment shorting, faulty wiring, and the risk of shock or even fatal electrocution.

Exposure to ultraviolet or infrared light

Hot work activities such as welding can expose workers to potentially dangerous UV or IR radiation. If workers are exposed to this type of non-ionizing radiation, it can damage their skin or eyes.

Exposure to hazardous fumes

Hot work can produce hazardous fumes that pose major health risks to workers. Vapors can cause respiratory illnesses, burns, flu-like symptoms, and eye damage.

Flying sparks can cause a fire or explosion.

When an activities such as welding are done, sparks can fly, and these sparks can cause fires or explosions if they come in contact with flammable materials, waste, or hazardous materials.

Conducting heat through pipes

Heat can be conducted through metallic materials such as pipes, and when the heat is transferred, it can come into contact with flammable, combustible, or otherwise hazardous materials.

Skin injuries through contact with hot materials or equipment

If workers touch equipment, debris, or very hot surfaces or come into contact with open flames or sparks, they may suffer skin injuries such as thermal burns, friction burns, or cuts. Personnel working in the area or passing through may also be injured by sparks. Especially if the area is not properly isolated and access restricted or if there is no additional protection such as a fire blanket. The above are just some of the this type work hazards that may apply to your workplace. The specific hazards your workers face will depend on the people involved, the area where the hot work activities are performed, and any potential hazards that are specific to your equipment and workplace. Before implementing control measures, you should make sure that you have considered all possible risks.

Fire hazards from hot work

Hot work has the potential to unite all three parts of the fire triangle: oxygen, fuel, and an ignition source.

Oxygen is present in the ambient air. Unsafe practices involving pure oxygen can cause oxygen enrichment (more than 22% by volume) in the workplace.

Fuel includes anything that is combustible. Examples of common fuels include:

-

- Building materials such as wood, plastic, insulation, and roofing materials, including those in hidden spaces.

-

- Flammable gases or liquids such as fuel, paint, and cleaning solvents

-

- Simple combustible materials such as cloth, paper, cardboard, wood, and furniture

Ignition occurs when there is a sufficient heat source to ignite the fuel. This source can occur through the direct or indirect application of heat. Direct applications of heat include welding, cutting, and burning.

Indirect applications include heat transferred through metal surfaces to fuel sources on the other side (e.g., through the other side of a wall) and sparks transferred to a distant fuel source (e.g., to a liquid pool or other combustible material).

Flying sparks are a major hazard from hot activity and can easily become lodged in cracks, pipes, holes, and other small openings, where they can potentially cause fires and even explosions.

Wastes and residues generated by hot work, such as shavings, molten metal, slag, and ashes, are often combustible.

Hot work can cause pipes to heat up significantly, easily transfer to another flammable surface through the conduction process, and cause a fire.

In certain environments, there may be potentially explosive vapors or gases in the air that are highly flammable and can ignite if exposed to work. Likewise, this work can create fumes, which in turn create an explosive atmosphere.

Methods for improving safety and preventing hot work hazards

The consequences of hot activity hazards can be severe and costly for any business. Injuries can result in death, disability, or layoffs. On the other hand, a serious fire can cause irreparable damage to buildings, facilities, and equipment. Both of these can even lead to legal consequences under certain circumstances. Therefore, it is important to understand how to implement proper safety controls in this work. For this purpose, the standards and requirements of it should be known.

NFPA 51B Standard Requirements for Hot Work Safety

NFPA 51B is America’s most comprehensive hot work safety document. This type work can be dangerous, especially when there are combustible materials in the area. NFPA 51B, Standard for Fire Prevention During Welding, Cutting, and Other Work, helps you reduce the risks associated with this type work projects. Requirements include welding, heat treatment, grinding, and other applications where sparks or flames are likely to occur.

This reliable welding standard provides general requirements to ensure that those involved in this type work are aware of fire and explosion hazards, prevention, and safety measures in areas where combustible materials can cause a fire or explosion.

This standard also provides clear guidance on the management of activities and safety requirements for PAIs, fireguards, welders, fire marshals, and hot work operators in any environment.

As such, NFPA 51B covers the safe use of welding, cutting, heat treating, grinding, and hot work equipment.

European Standard BS 9999 for Hot Work

Also, due to the high-risk nature of this work, the European standard BS 9999 and the Health and Safety Executive (HSE) outline various safety procedures that organizations must adhere to. Their purpose is to protect workers from the dangerous aspects of hot work and prevent fires. BS 9999 states that “hot working should only be carried out if no satisfactory alternative method is possible.” Therefore, it is important to consider every possible alternative to completing a task before deciding to proceed with it. For example, determine if bolting is the right solution instead of welding. In a similar vein, avoid cutting torches by using manual hydraulic shears instead. In some situations, hot work is unavoidable. If so, permission must be created before you begin. The permit is very important because it specifies the safety measures that everyone must follow to minimize the risks associated with the work.

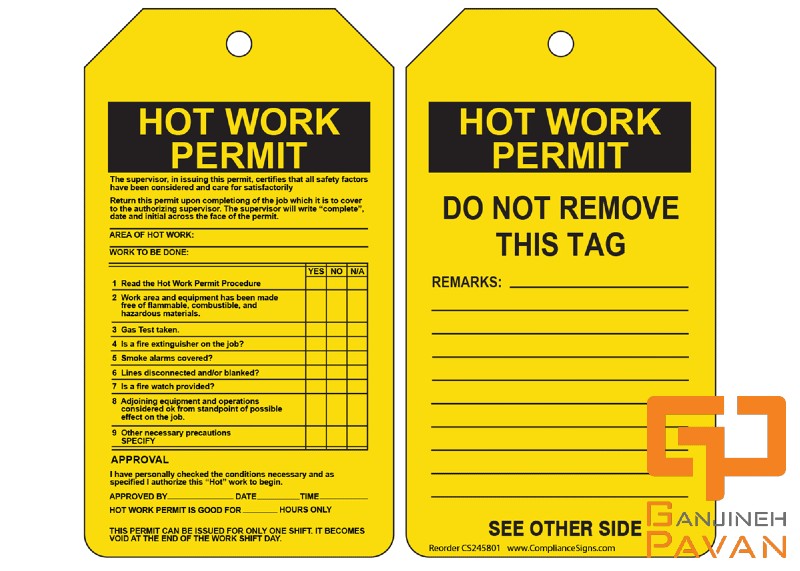

Preparation of a Hot Work Permit

Due to the risk of work, obtaining a hot work permit is mandatory. A hot permit is a permit that is issued in some countries and in some workshops to perform this work such as welding, soldering, cutting, grinding, and drilling in the presence of flammable materials that can increase the risk of fire. To be accompanied is required.

According to BS 9999, a hot work permit procedure, which may be part of an overall safety permit work procedure, must be followed before any hot work is permitted in or near a building. It is necessary to ensure that the correct actions are taken before starting hot activity, during operations, and afterward.

Parts of a hot work permit

A hot work permit includes the following sections:

-

- Work Details: What kind of hot work should be done?

-

- Risks and Challenges: What are the risks associated with it work?

-

- Precautions and procedures: What steps and safety measures are taken and applied before and during work?

-

- Personal protective equipment: Should people wear protective glasses, face masks, and gloves?

-

- Reference to Isolation and Isolation Certificate: Does the adjacent equipment need to be isolated before starting work?

-

- Licensing and Acceptance: This includes those involved in the creation, implementation, and follow-up of the license.

-

- Training and Competence: Do people need training before they can do this work?

-

- Handover Procedures: If people are doing the work shift, what procedure does the workplace follow to ensure that they are safely transferred?

-

- Cancellation and return procedures: Who is responsible for handling the work once it is finished or needs to be cancelled?

Understanding the duties and knowing exactly who is involved makes licensing relatively simple. A competent person not directly involved in the hot work should prepare and authorize the program, but the input and commitment of all participants are essential.

You are legally required to perform all operations while demonstrating a safe system of work. Therefore, before starting any hot work activity, you should prepare a hot work permit system.

The permit should include details of the work to be done, how and when it will be completed, and precautions to ensure the activities are as safe as possible. This license must be prepared by a person who has the relevant skills, knowledge, experience, and training.

Hot work control measures to keep workers safe

Once you have identified the hazards of hot work in your workplace, you must plan and implement control measures to make your workplace a safer environment and protect workers from harm.

Just like hazards, the control measures you implement should be unique to your industrial, commercial, and workplace operations.

In the following article, we examine some hot work control measures to prevent possible risks.

Avoid hot work if possible

Hot work is inherently dangerous. You can never completely eliminate the dangers of working in excessive heat. So avoid hot work completely, if possible.

Consider alternative processes and activities that could achieve the same result. For example, instead of welding, can items be joined together using mechanical methods such as nuts and bolts or screw connections?

Clear the hot work area of flammable materials

A work space that is cluttered with unnecessary materials, equipment, trash, or furniture has a greater fire potential than a clean and tidy area.

One of the most important ways to prevent fire hazards from hot work is to clean the area before starting. This includes the removal of flammable and explosive materials and liquids within a five-meter radius of the work. Depending on the type of work, site managers may need to expand this radius.

It is also necessary to ensure that there are no flammable or explosive vapors, gases, or dust in the atmosphere. If there may be a problem, gas or vapor monitoring should be done through a gas and fire monitoring system and a suitable gas detector.

By keeping the hot work area clean, you minimize fire safety hazards. This control measure can also reduce other health and safety hazards, such as the risk of slips and falls, which, when combined with hot work hazards, can have catastrophic consequences. A clean and tidy area also allows workers to safely evacuate the building in the event of a fire.

Hot work often produces sparks that can easily enter holes or cracks in floors, walls, and ceilings or land on combustible materials. Therefore, take the time to cover these areas with suitable flame-retardant sheets and special fire-retardant blankets before starting work. Combustible floors can be covered with wet sand to prevent ignition.

In cases where you cannot completely clear the area of combustible materials, use suitable fire- and flame-retardant coverings on them, but make sure you cover them completely and monitor the area carefully.

Performing hot work in a designated or prepared area

It is very important that hot work be done in an area specifically designed for it, but some areas are understandably not built to withstand it. For example, if a contractor needs to do welding work on a pipe in a staff room kitchen, it is obvious that this part of the building is not specifically designed to minimize hot work hazards.

However, it is entirely possible to assess an area and prepare it for hot work, such as applying protective coatings as described above. This is as true for five-minute tasks as it is for tasks lasting several hours or days.

If hot work activities are regularly performed by your workers, you may want to designate an area of your workplace for welding, soldering, brazing, and other work that involves heat or an open flame. These areas should be designed to be as safe as possible, so flammable or combustible objects should be minimized and covered with protective and fire-resistant materials. It should also be possible to restrict access to these areas.

Having a designated hot workplace can make it easier to minimize hazards and eliminate or control hazards, but isolating an entire work area is not always possible for many businesses. If hot work is done in a public area, preparations must be made for it.

When selecting an area for activities that involve heat and flame, avoid areas where hazardous materials are stored, as these can increase the potential for fire in a workspace. If it is not possible to perform hot work away from hazardous materials, ensure that you comply with relevant regulations and standards and that materials are stored safely and securely.

Make sure the people doing the hot work are trained to do it

The dangerous nature of hot work means that it should only be carried out by people who have the necessary skills, knowledge, experience, and training to carry out tasks to a high standard while implementing control measures and monitoring health and safety standards.

If there are no workers in your organization with the required or desired skill level, you may want to train an individual or a group of employees for these tasks. Alternatively, you can hire an outside contractor with the ability to complete hot work while effectively managing risks.

Gas or vapor monitoring in the area used for hot work

Air contaminated with gas or vapor can cause health and fire hazards. For example, some gases are toxic, while others are flammable or explosive. Workers must be able to control gases and vapors in the air to ensure they are working in safe conditions. However, since the gas is not visible, special monitors, such as various types of gas detectors, must be used.

Fire safety systems for hot work

Those doing and supervising this type of work must understand the fire safety procedures in place.

In particular, they should be aware of the following:

-

- Whether the area has a proper fire extinguishing system, such as an extinguisher or sprinkler, or not

-

- How to activate the fire alarm, where to evacuate in an emergency, and how to contact emergency or fire officials.

-

- How to avoid false alarms. Do certain detectors need to be temporarily disabled? If so, these should be reactivated as soon as the job is done.

-

- Which fire extinguishers are necessary? At least the supervisor should receive firefighting training. In addition, the site should have at least two suitable extinguishers based on the type of hot work being done.

Safety tips related to the completion of work

When hot activities are stopped, workers must properly handle the materials used.

For example, consider the following:

-

- Completely switch off LPG burners and lamps and allow them to cool after use.

-

- Remember to let them cool down before replacing the cylinders, and remove the gas cylinders completely when you’re done.

-

- Before returning to electric hot air blowers, properly shut them down, unplug them, and cool them down.

-

- Immerse the ends of welding rods in water before safely and properly disposing of them.

-

- If hot work produces flammable materials, such as metal shavings, clean the area.

Hot work supervision

Proper monitoring of hot work is useful for monitoring safe work practices, but is primarily necessary for monitoring the environment afterward. At least one hour after the completion of the work, the target area should be monitored to ensure that the fire does not start. This is very important because it is difficult to see a spark that has gone through a hole until it starts to smoke.

A fire watcher can be anyone who has responsibility and is aware of the hazards, such as a supervisor or someone who has been involved in the work. They must be trained in firefighting and must monitor the main work area as well as adjacent rooms and the floors immediately below and above.

Doing so ensures that they are ready to immediately suppress any smoke or fire and prevent an emergency.

Improve the overall fire safety of your workplace

Many hot work hazards are directly related to the overall fire safety of your workplace. For example, if your business has high fire potential, the risk factor for hot work increases. Similarly, if employees are not trained in fire safety, they may not know what to do in the event of a fire incident. If there is no readily available fire safety equipment on site, workers may not be able to effectively mitigate hazards.

One of the best ways to reduce hot work hazards is to improve the overall fire safety of your workplace. Fire safety policies and procedures must be up-to-date, relevant, and complete. Workers should be trained to use fire safety equipment such as fire extinguishers and fire blankets. They should also be aware of and trained in control measures such as smoke detectors, sprinklers, and evacuation procedures.

Flame-resistant clothing and personal protective equipment

As an employer, you must provide appropriate personal protective equipment (PPE) for workers participating in hot work. This can include fire-resistant clothing, respirators, eye protection, and other equipment designed to protect people from heat, sparks, hazardous fumes, and radiation.

Ganjineh Pavan: Safety and fire advisor

Ganjineh Pavan, as a firefighting consulting company, operates in the fields of supply, design, consulting, installation, implementation, and maintenance of projects in the fields of safety, fire alarm, fire extinguishing, F&G systems, and obtaining fire department approval for the completion of building work.

To improve the safety and security of the industrial, commercial, and residential work environment and to prevent fire and related risks, contact our experts in Ganjineh Pavan now.

References: