The goal of a smoke control management system (SCM) is to maintain a stable environment for building occupants, allow sufficient time for safe egress, and minimize property damage and work interruption. From Ganjineh Pavan’s articles, this article will examine what this system is and its working mechanisms.

During the conceptual design of a building, balancing form and function can be challenging while trying to comply with the mandate. Many variables, from walls and openings to areas and volumes of rooms, ventilation, weather, and building contents, all contribute to a building’s ability to provide the Required Safe Egress Time (RSET). Focusing on the impact of these variables through a performance-based design process often allows flexibility of architectural features to contribute to an ideal design vision.

Managing smoke control; an important part of the fire protection system

For many, hearing the term “Fire Protection” evokes the fire alarm system and fire suppression systems such as sprinklers. However, fire protection is a coordinated set of systems designed to protect occupants during a fire emergency.

Most people know that a sprinkler system is intended to control fire through wetting, and a fire alarm system is intended to warn occupants of a fire hazard. Many do not know that fire protection measures in residential environments are much more than the protective devices that can be seen. These protective measures can include, but are not limited to, fire detection, fire suppression, notification, egress considerations, interior cladding, horizontal and vertical fire barriers, ventilation, and smoke control.

What is a smoke control management system?

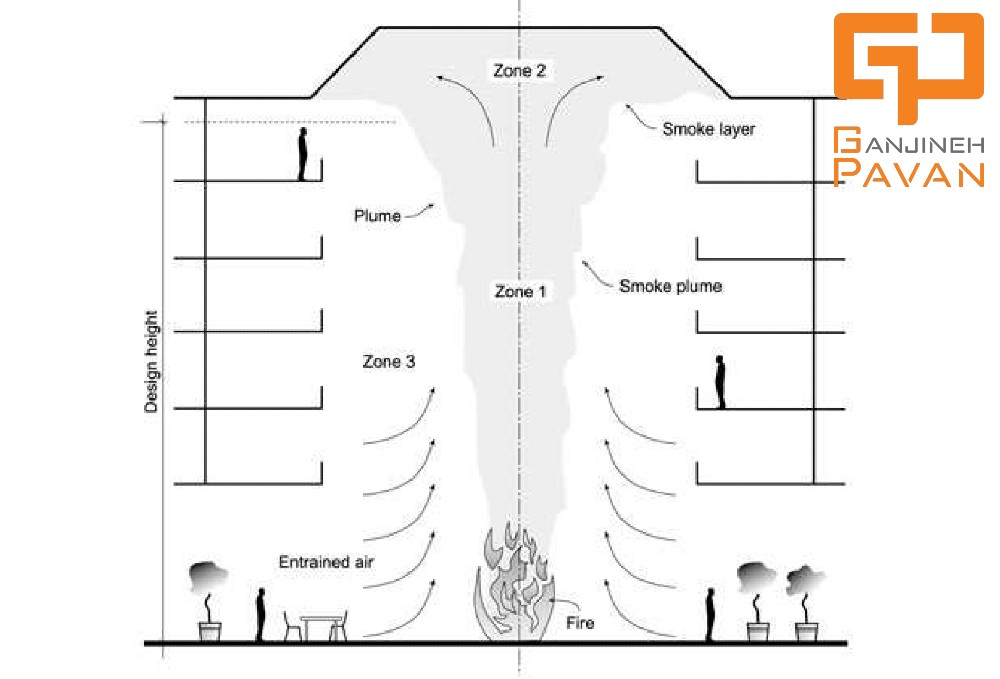

A smoke control system is used to control the movement of smoke and keep the exits steady during a fire. It is a vital part of systems that work with active and passive components to protect occupants from fire. Smoke Control Management (SCM) helps protect against fire, which is one of the most misunderstood aspects of the fire protection puzzle.

Smoke control and management are defined as an engineered system to control the movement of smoke. Smoke control management (SCM) systems consist of multiple components that work in tandem to provide a tolerable environment for the evacuation or relocation of occupants during a fire event.

Smoke control and management codes and standards

Modern building codes, standards, and technical references provide guidance for when an SCM system is needed and the measures necessary to comply with one. In the smoke control and management system, the following minimum codes, standards, and technical references should be included:

-

- International Building Code

-

- International Fire Code

-

- NFPA 92, Standard for Smoke Control Systems

-

- Society for Fire Protection Engineering (SFPE) Handbook.

-

- Handbook of Smoke Control Engineering

-

- ASHRAE Guide 1.5

It is important to note that each jurisdiction may apply all the previously mentioned codes, standards, and references along with the specified amendments/bulletins. The SCM designer must consider all codes, standards, references, amendments/bulletins, and revisions relevant to the project.

The approved building code determines when an SCM system is required. Note that this benchmark is specific to specific applications and does not consider performance-based options for alternative tools and methods.

SCM system design features

Below is a general list of design features that require SCM systems from the 2018 edition of the IBC (International Building Code):

-

- Tall Buildings (IBC, Section 403)

-

- Vestibules (IBC, Section 404)

-

- Underground Buildings (IBC, Section 405)

-

- Group I-3 Buildings (IBC, Section 408.9)

-

- Larger Stages, Platforms, and Technical Production Areas (IBC, Section 410.2.7.2)

-

- Special recreational buildings with an occupant load of 50 or more (IBC, Section 411.1)

Smoke control management approaches

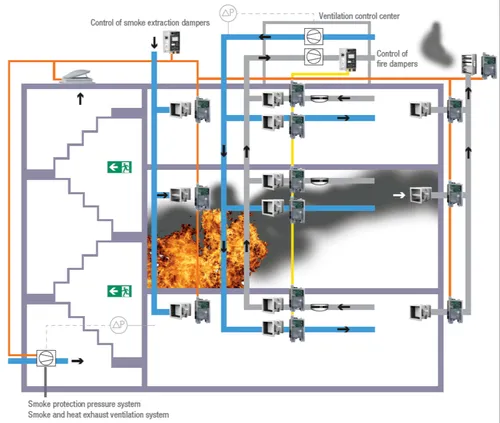

The SCM designer has a variety of approaches to incorporate as the basis of his design. The following methods are commonly used to design SCM, passive, pressure, air flow, exhaust, and natural ventilation systems.

Passive SCM systems

These systems prevent the transfer of smoke and fire into a physical barrier/smoke zone through a listed building complex. These assemblies are usually rated as fire/smoke barriers (e.g. listed walls and floors). It is common to have openings inside barriers (such as doors/windows/shutters) which also have their approval list.

Pressurization smoke control management systems

These pressurization systems take into account the pressure difference across a barrier/smoke zone so that during a fire event, smoke over a low-pressure zone is not transported to a high-pressure zone. For example, a smoke-tight enclosure (e.g. a pressure step) may be considered.

Airflow SCM systems

Airflow is used to prevent the flow of smoke out of the fire zone for building elements that have fixed openings. Airflow is determined at a rate that is related to fire conditions and smoke temperature. Also, these parameters are considered based on the desired opening geometry. These types of airflow control smoke management systems are for smaller openings, such as transom windows.

Smoke control management exhaust systems

Exhaust fan systems use mechanical means to draw smoke out of large, closed spaces in order to maintain stability. These systems are widely used and usually protect high-volume spaces (such as hallways).

Natural ventilation SCM systems

These types of smoke control management systems use the effects of smoke buoyancy and vents (mechanical or manual) to allow smoke to escape from space through an opening to the outside of the building. These systems are usually not used in climates that have inconsistent weather because different temperatures and scattered wind speeds can have negative consequences.

These systems can be found in the smoke-proof enclosures of many atriums. In general, designing these systems to properly adapt to environmental variables is the most challenging.

Smoke control management system design

Given the variety of smoke control management methods, any smoke control management system can be designed using one or a combination of existing approaches. When an SCM system uses other building components/systems that are used for normal building operations (for example, the heating, ventilation, and air conditioning or HVAC system), it is called a non-proprietary system. A smoke control management system that has its own independent equipment/purpose is referred to as a dedicated system. Each of the selected options should consider the variables presented at the project/site location.

When a project requires an SCM system, it is generally considered best practice that the proposed approach and supporting documentation be agreed upon with the owner, the design team, and the authority having jurisdiction (AHJ) before further development of the system. This agreement is based on a design brief that conceptualizes the smoke control management system and the primary design parameters involved in the project. The design brief specifies the responsibilities of all parties responsible for the system’s purpose during development.

Modeling of a smoke control management system

As the design of the smoke control management system progresses, a report documenting the intent, assumptions, sequence, methods of operation, and environmental variables is compiled into a logical analysis. All SCM systems are modeled by manual empirical calculations or computational fluid dynamics (CFD) programs. These models are essentially playbooks that demonstrate compliance when at least the following project/site-specific variables are included in the model:

-

- chimney effect

-

- Thermal effect of fire

-

- wind effect

-

- HVAC systems

-

- Climate

-

- Duration of operation

-

- Interaction of smoke control system

After the logical analysis is completed, it is required to be submitted in the construction documentation phase and accepted by the AHJ before the system is constructed and commissioned.

Smoke control management system inspection

Before completing the installation of the SCM system, the design team must designate a design specialist who can perform a special inspection (SI) of the system. The SI specialist should have an extensive background in fire protection engineering, mechanical engineering, and certification as an air balancer.

Once an SI specialist is employed by the design team, they will prepare a special inspection and test report that will be sent back to the authority having jurisdiction (AHJ) for approval. This report describes the test methods that affect the smoke control management system. The purpose of the SI report is to apply the SCM system to ensure proper compliance as designed/verified in the logical analysis and related design documents.

It is important that the smoke control management system be previously tested by the SI and that the design team coordinate roles, responsibilities, and efforts accordingly/effectively. After the SI is completed, a final report, including relevant tests and field measurements (e.g. airf low/pressure difference, amperage/voltage, etc.), is documented and submitted to the AHJ for the record.

Continuation of periodic inspections and tests

Continuous tests and inspections are required for SCM systems to ensure correct modulation, sequencing, and system operation according to the original logical analysis and design documents. Modern systems are equipped with automated diagnostic test programs (e.g. UUKL Smoke Control Equipment Checklist software) that interface with various data points in the smoke control management system.

If a part of the system malfunctions, a notification is sent to the control system, allowing facility personnel or service technicians to report the error. Additionally, there are guidelines for when a smoke control management system is inspected for compliance.

Periodic testing is required for dedicated systems at least every six months, and non-dedicated systems are tested at least annually. Although an existing system may appear to be working, it must be inspected regularly.

If any part of the system is modified or changed, it is best to ensure that the original design intent is maintained. Otherwise, a system redesign and updates to the original logic analysis are required. This update requires AHJ approval.

The last word of the smoke control management system

Fire protection takes many forms, from stand-alone systems to a network of planned integrated systems. The smoke control management system combines the principles of independent systems and a network of intelligent systems in a proprietary and non-proprietary system.

The methodology behind each system is supported by engineering principles and empirical research specific to each project and location. The framework documents for each system the environmental effects, building geometry, fuel loads, and any agreed assumptions and considerations, which can be found in the rational analysis. Smoke control management system quality assurance guidelines for commissioning and ongoing inspections, tests, and maintenance are specified for each of these systems. Although smoke control/management systems vary, the basic goal is to create a stable environment for evacuation during a fire event.

Ganjineh Pavan, consultant, and administrator of the smoke management and control system

Ganjineh Pavan Co., is a fire consultant and contracting authority in Tehran province, providing engineering and design services for smoke control systems including passive smoke chamber, shaft/zone pressure, vestibule/floor smoke exhaust, and post-fire smoke clearance.

Ganjineh Pavan has extensive experience in designing smoke control systems for complex building environments with a deep understanding of fire science and human behavior. We use advanced modeling tools to simulate smoke development and human evacuation, and we work closely with clients to develop cost-effective smoke control solutions to enable a higher level of building and architectural design freedom.

To receive any free advice on the company’s activities, contact our experts in Ganjineh Pavan now.

References: