F&G system or flame and gas detection system

What is F&G system or flame and gas detection system?

F&G System stands for Fire and Gas Detection System. F&G is a safety system designed to detect and alert people to the presence of fire or hazardous gases in an industrial or commercial facility.

The F&G system or the flame and gas detection system has advanced and special capabilities and due to its high cost, it is mostly used in high-risk areas of industrial projects such as petrochemicals, refineries, power plants, and industrial factories. Anti-explosion equipment is designed and manufactured.

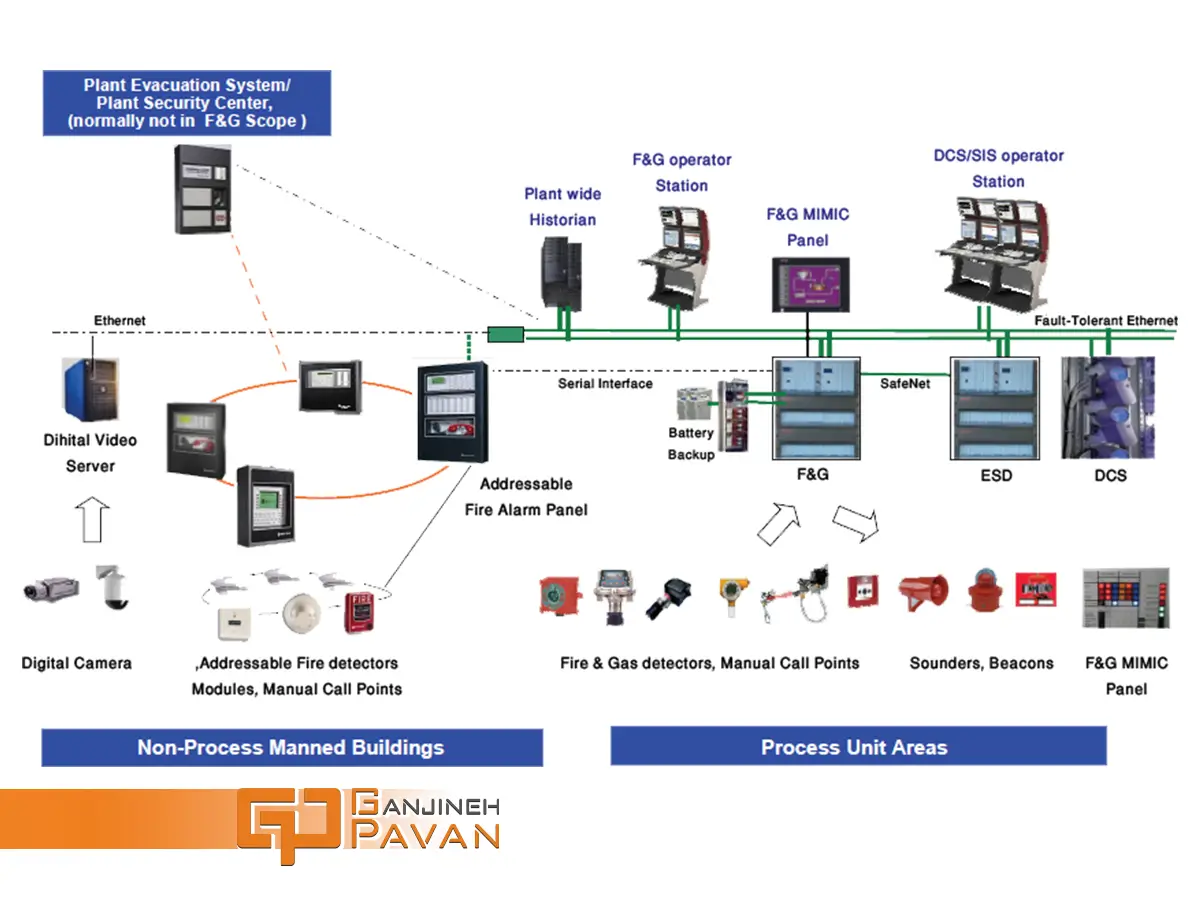

These systems consist of the control panel center of detectors or flame, gas, smoke, heat, and smoke and heat combination detectors, which, along with warning equipment such as sirens and fire flashers, inform people about the occurrence of fire.

The F&G system is used in a space that has a high-risk factor or is considered a Hazardous Area.

The areas that are covered by the F&G system are called Zones and its different parts are named Z1, Z2, and Z3 based on the explosion risk in that area.

Therefore, one of the most important advantages of using F&G equipment is that it informs us of the occurrence of fire in the shortest time and with the highest reliability factor.

Currently, Ganjineh Pavan Company, as a company approved by The Fire Department of Tehran Province, is ready to design, supply, install and operate the best types of F&G systems or flame and explosion-proof gas detection systems with the highest reliability factor, according to your expectations and the risk level of your work space.

Ganjineh Pavan Company has played a role in this field as an EPC and intends to provide decent services worthy of the dignity and position of its customers. Also, in this direction, we try to provide the best and highest quality products in the shortest time and at the lowest cost.

Differences between F&G System and Fire Alarm

The F&G system is designed to monitor and respond to both fire and potentially hazardous gases in industrial environments. This system consists of sensors and detectors that can detect fire, combustible gases, and toxic gases. These sensors must be strategically placed in areas with high fire or gas leak risks. On the other hand, fire alarm systems typically deal with domestic or municipal gases and usually control fires before they start or intensify. Fire detection equipment in fire alarm systems detects early signs of fires, such as smoke or heat. Fire alarm systems primarily focus on detecting and alerting occupants about the presence of fire within a building or structure.

Fire alarm systems, by detecting smoke, heat, or manual activation, trigger alarms to alert individuals inside the building and often notify emergency services. The goal is to ensure the safe evacuation of individuals and facilitate a quick response to the fire.

Detection Range:

- F&G System: Monitors fire and gas hazards and addresses a broader range of potential threats in industrial environments.

- Fire Alarm System: Primarily focuses on detecting and alerting occupants about the presence of fire within a building.

Installation Environment:

- F&G System: Typically used in industrial environments with higher risks of fire and gas leaks, such as petrochemical plants, refineries, and manufacturing facilities.

- Fire Alarm System: Installed in commercial and residential buildings to ensure occupant safety during fires.

Components of the F&G System

The F&G system consists of several components, each playing a crucial role in detecting and managing fire and gas hazards. These components include:

-

Detectors:

- Flame Detectors: Detect the presence of fire flames and are usually used in high-risk fire environments.

- Gas Detectors: Designed to identify the presence of combustible and toxic gases. Gas detectors can be point or linear.

- Smoke Detectors: Detect smoke, indicating the onset of a fire.

- Heat Detectors: Detect temperature changes and alert when there is a sudden rise in temperature.

-

Control Panel:

- The control panel is the brain of the F&G system, receiving and processing information from the detectors. It can be controlled locally or remotely and is responsible for issuing alarms and activating automatic response systems.

-

Alarm Devices:

- Sirens: Produce audible alarms to alert individuals of danger.

- Flashers: Activate visual alarms such as flashing lights to draw attention to the danger.

-

Automatic Response Systems:

- These systems include sprinklers and fire suppression systems that automatically activate to extinguish or limit the spread of fire.

-

Communication Network:

- A network that connects detectors, the control panel, and alarm devices. This network can be wired or wireless and must be reliable and fast.

-

Power Supply Equipment:

- Responsible for providing power to the system, usually including emergency power sources such as batteries to ensure the system operates during a main power outage.

Advantages of Using the F&G System

Using the F&G system in industrial and high-risk environments offers numerous benefits, including:

-

Rapid and Accurate Detection:

- F&G systems can quickly detect fires and gas leaks, helping to prevent the spread of incidents and reduce damages.

-

Increased Employee Safety:

- Timely warnings allow employees to evacuate dangerous areas quickly and implement safety measures, enhancing workplace safety.

-

Maintaining Industrial Operations:

- By swiftly identifying and responding to hazards, the F&G system prevents sudden operational halts, helping maintain continuous production.

-

Reduced Financial Losses:

- Early detection and immediate actions reduce fire and gas leak-related damages, leading to lower repair and maintenance costs and preventing significant financial losses.

-

Compliance with Safety Standards:

- Using the F&G system helps comply with safety standards and regulations for industrial environments, avoiding penalties and legal issues.

-

Ensuring Proper Equipment Functioning:

- F&G systems continuously monitor the performance of detectors and alarm devices, alerting to any faults or issues to take necessary actions.

Disadvantages of Using the F&G System

Despite numerous benefits, using the F&G system may also involve some disadvantages, including:

-

High Cost:

- Installing and maintaining F&G systems can be expensive due to the need for advanced equipment and technologies, posing challenges for some organizations.

-

Complex Installation and Setup:

- Installing and setting up the F&G system requires technical expertise and engineering, making the process complex and time-consuming.

-

Need for Regular Maintenance:

- These systems require regular maintenance and periodic inspections to operate optimally, potentially increasing costs and time.

-

Risk of Human Errors:

- Incorrect settings and human errors during installation and maintenance can result in false alarms or improper hazard detection.

-

Environmental Limitations:

- Some F&G systems may perform less effectively under specific environmental conditions, such as extreme temperatures, high humidity, or dusty environments.

Applications of the F&G System

F&G systems are used in various industries and environments with potential fire and gas hazards. Some of these applications include:

-

Oil, Gas, and Petrochemical Industries:

- Refineries, petrochemical plants, and oil terminals use F&G systems to detect and manage fire and gas hazards.

-

Power Plants:

- Thermal and electric power plants use F&G systems to enhance safety and prevent incidents.

-

Oil Rigs:

- Offshore and onshore oil rigs require F&G systems due to high risks of fire and gas leaks.

-

Mines:

- Underground and surface mines use these systems to monitor fire and gas hazards.

-

Laboratories and Research Centers:

- Chemical laboratories and research centers handling flammable materials and toxic gases use F&G systems for safety.

-

Industrial Factories:

- Manufacturing plants such as steel mills, cement factories, and chemical industries use F&G systems to increase safety and prevent incidents.

The main activity of Ganjineh Pavan in the field of flame and gas detection system:

- Oil, gas, and petrochemical industries

- Power plant industries

- Oil rigs

- Oil terminals

- Mines

- Labs

- Drilling

- Chemical centers

- Industrial factories (steel, cement, etc.)

Some prominent and selected brands of F&G system or fire and gas detection system that are offered in Pawan’s treasury:

- Honeywell

- MSA

- Scam System

- Draeger

- Spectrex

- Crowcon

- TYCO

- Simtronics

- General Monitors

- Net Safety

- MEDC

- E2S

- Kromamec

- Cooper

- Fenwal

Why Choose Ganjineh Pavan?

Ganjineh Pavan is a leading company in this field, offering consulting, training, design, engineering, supply, procurement, installation, execution, and maintenance services. Currently, Ganjineh Pavan is listed on the vendor list of the Tehran Fire Department. Utilizing the experiences and capabilities of its human resources and employing the latest technologies and standards, the company is proud to provide its clients with the best and most appropriate services. Ganjineh Pavan also provides practical and useful information to its clients to prevent potential risks and aims to comprehensively address all their needs.

Conclusion

Fire and Gas (F&G) systems play a crucial role as one of the most important safety tools in high-risk industrial environments, identifying and managing potential hazards. These systems use advanced technologies and a combination of various detectors to quickly detect and respond to fire and gas incidents.

Given the high importance of safety in the oil, gas, petrochemical, power plant, mining, and industrial factory sectors, the use of advanced F&G systems is indispensable. These systems provide numerous benefits to various industries by reducing response time to incidents, increasing employee safety, and minimizing financial and operational damages. Despite challenges such as high costs and the need for regular maintenance, the advantages of F&G systems in ensuring safety and maintaining industrial operations far outweigh these challenges. Companies like Ganjineh Pavan play a significant role in designing, supplying, and installing these systems, helping industries achieve higher safety and efficiency levels.

Ultimately, choosing and properly implementing an F&G system is not just a legal and safety standard requirement but also a strategic investment to protect employees and industrial assets. By utilizing advanced F&G systems and continuously monitoring hazards, a safe and secure environment for industrial activities can be created, preventing unfortunate incidents.